Recently, while discussing product innovation and enhancing market competitiveness with a brand product manager, we identified three key innovation areas for the future of wooden Montessori products:

1️⃣ Modularity and Durability (“Grow with Me” Feature)

Parents are tired of buying furniture that lasts only six months.

Innovative Solution: We’re developing transformable cribs (convertible into desks) and Pikler triangles (evolving into playhouses).

Business Value: This design supports higher retail pricing and boosts brand loyalty (LTV) by extending product lifespan from months to years within households.

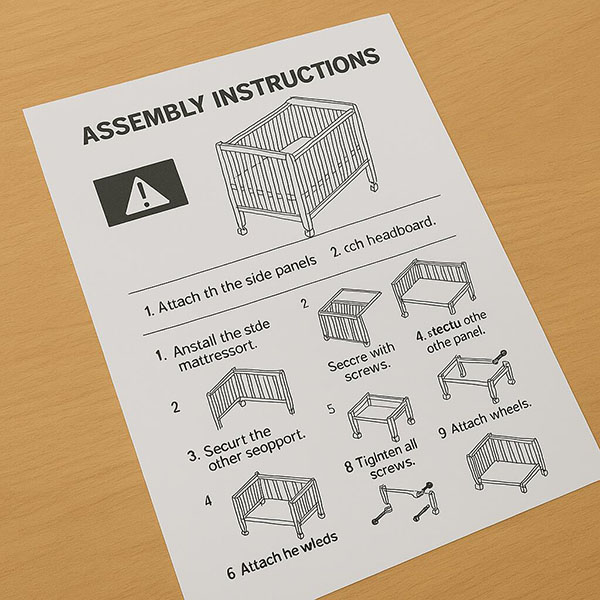

2️⃣ “Zero-Frustration” Assembly Experience

Out-of-the-box usability is the product’s first test.

Innovation: Precision CNC machining creates smart mortise-and-tenon joints, enabling pre-embedded hardware and a “tool-free” assembly system.

B2B Value: Significantly reduces customer return rates caused by “assembly frustration” or damaged parts.

3️⃣ Logistics-Optimized Design (Smart Flat-Pack) Shipping “air” eats into profits.

Innovation: Complex structures (e.g., learning towers) are engineered to disassemble into ultra-thin flat-packs while maintaining structural rigidity.

B2B Value: Optimizes container load quantity (CLQ) and reduces last-mile delivery costs.

Question: Are you still sourcing “static” products, or building a flexible product line that solves modern parenting challenges?

If you have ideas requiring complex engineering, our team welcomes the challenge. Let’s prototype the future of play together.