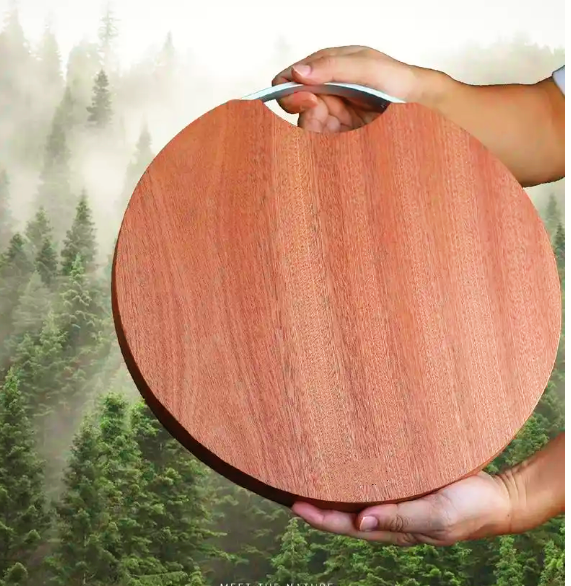

How Sustainable Materials Are Transforming the Cutting Board Industry

Sustainability has become a driving force in nearly every industry, including kitchenware and home goods. The cutting board industry, in particular, is undergoing a major shift as eco-friendly materials, innovative manufacturing processes, and consumer demand for sustainability push brands toward greener alternatives. This article explores how sustainable materials are shaping the future of cutting boards, the environmental benefits they offer, and what this means for manufacturers, retailers, and consumers alike.Sustainability has become a driving force in nearly every industry, including kitchenware and home goods. The cutting board industry, in particular, is undergoing a major shift as eco-friendly materials, innovative manufacturing processes, and consumer demand for sustainability push brands toward greener alternatives. This article explores how sustainable materials are shaping the future of cutting boards, the environmental benefits they offer, and what this means for manufacturers, retailers, and consumers alike.

www.woodencraftsliving.com

1. The Shift Toward Sustainable Cutting Board Materials

Traditional cutting boards are often made from hardwood, plastic, or composite materials, but these have significant environmental drawbacks. Hardwood requires deforestation, plastic contributes to pollution, and composite boards often contain resins or adhesives that aren’t biodegradable.

To combat these challenges, the industry is turning to sustainable materials that reduce environmental impact while maintaining durability and functionality.

2. Key Sustainable Materials in Cutting Board Manufacturing

a. Bamboo: The Eco-Friendly Favorite

Bamboo has emerged as one of the most popular sustainable alternatives to hardwood and plastic.

✅ Fast-growing & renewable – Bamboo can grow up to 3 feet per day, making it one of the most sustainable plants on Earth.

✅ Naturally antimicrobial – Reduces the growth of bacteria and mold without requiring chemical treatments.

✅ Biodegradable & compostable – At the end of its lifespan, a bamboo cutting board can break down naturally.

✅ Durable & lightweight – Bamboo boards are strong, yet 30% lighter than traditional hardwood options.

➡ Challenges: Some bamboo cutting boards use formaldehyde-based adhesives, which can release volatile organic compounds (VOCs). Manufacturers must ensure they use non-toxic, food-safe adhesives.

www.woodencraftsliving.com

b. Reclaimed & FSC-Certified Wood: Reducing Deforestation

Instead of cutting down new trees, many brands are now using reclaimed wood or FSC-certified (Forest Stewardship Council) timber to produce sustainable cutting boards.

✅ Reclaimed wood repurposes old materials, preventing unnecessary tree harvesting.

✅ FSC certification ensures responsible forestry, reducing environmental damage.

✅ Long-lasting and repairable – Unlike plastic, wooden cutting boards can be sanded and refinished to extend their lifespan.

➡ Challenges: Reclaimed wood can be difficult to source in large quantities, and FSC-certified wood is often more expensive than non-certified options.

c. Recycled Plastic: A Second Life for Waste

While plastic cutting boards are traditionally seen as environmentally harmful, some companies are using recycled plastic to create durable, long-lasting boards.

✅ Reduces landfill waste by repurposing discarded plastic.

✅ Highly durable & dishwasher-safe – Unlike wood, recycled plastic boards don’t absorb moisture.

✅ Can be 100% recyclable at the end of its lifespan, contributing to a circular economy.

➡ Challenges: Not all recycled plastic cutting boards are BPA-free, and microplastic shedding during knife use remains a concern.

www.woodencraftsliving.com

d. Paper Composite & Resin-Free Biodegradable Boards

New advancements in paper composite technology are creating ultra-durable, eco-friendly cutting boards that mimic the strength of traditional materials.

✅ Made from compressed recycled paper and plant-based resins, making them biodegradable.

✅ Water-resistant and knife-friendly, making them a great alternative to plastic.

✅ Heat-resistant up to 350°F, meaning they can double as trivets.

➡ Challenges: Paper composite boards can still contain resins, which may not always be fully biodegradable. Brands must focus on developing 100% natural resin alternatives.

e. Plant-Based & Mycelium-Based Innovations

Emerging materials like mycelium (mushroom-based) biocomposites and hemp-based plastics are starting to enter the cutting board industry.

✅ Fully biodegradable & compostable, leaving zero waste.

✅ Requires less water and energy to produce than traditional materials.

✅ Non-toxic & chemical-free, making them safer for food contact.

➡ Challenges: These materials are still in early-stage development and require scalability for widespread adoption.

3. How Sustainable Cutting Boards Benefit the Environment

🌍 Lower Carbon Footprint – Sustainable materials like bamboo and reclaimed wood require fewer resources to grow and process compared to traditional hardwoods and plastics.

🌱 Reduced Waste & Pollution – By using recycled materials, the cutting board industry can significantly cut down on plastic waste and landfill contribution.

♻ Circular Economy Adoption – Encouraging recycling, composting, and upcycling ensures cutting boards have minimal environmental impact throughout their lifecycle.

🚰 Less Water & Chemical Usage – Sustainable manufacturing processes use fewer toxic chemicals and less water compared to traditional wood treatment and plastic molding.

4. Challenges & Future Innovations in Sustainable Cutting Boards

🔹 Scaling Production of Alternative Materials – While sustainable options exist, mass production can still be challenging due to high costs or limited supply chains.

🔹 Consumer Education & Awareness – Many consumers still don’t understand the environmental impact of their kitchen tools, requiring better marketing and awareness campaigns.

🔹 Balancing Cost & Affordability – Sustainable cutting boards often have higher price points. Brands must find ways to keep prices competitive.

Future Innovations to Watch:

✅ Nano-antibacterial coatings on bamboo & FSC-certified wood for extra hygiene.

✅ Zero-waste manufacturing with carbon-neutral production processes.

✅ Biodegradable cutting boards made from 3D-printed plant fibers.

5. How Manufacturers & Retailers Can Adapt to the Sustainable Shift

For cutting board manufacturers and retailers, embracing sustainable materials isn’t just about following a trend—it’s about future-proofing their business. Here’s how they can stay ahead:

✔ Source responsibly – Partner with suppliers who offer FSC-certified, recycled, or upcycled materials.

✔ Invest in research – Explore new material science advancements, such as bio-based resins and composite alternatives.

✔ Implement sustainable packaging – Reduce waste by using biodegradable or recyclable packaging.

✔ Educate consumers – Use marketing strategies that highlight the eco-friendly benefits of sustainable cutting boards.

Conclusion: A Greener Future for the Cutting Board Industry

Sustainable materials are redefining the cutting board industry, offering eco-conscious, durable, and innovative alternatives to traditional wood and plastic. As consumers become more environmentally aware, the demand for responsibly sourced, biodegradable, and recycled cutting boards will only continue to grow.

For manufacturers and retailers, adapting to these sustainability trends isn’t just an option—it’s a necessity. By integrating bamboo, reclaimed wood, recycled plastics, and next-gen plant-based materials, brands can lead the way in a more sustainable, ethical, and future-focused industry.

Key Takeaways:

✅ Bamboo, FSC-certified wood, and recycled plastics are leading sustainable cutting board materials.

✅ Paper composite and plant-based bioplastics are emerging as innovative eco-friendly alternatives.

✅ The industry must address challenges like affordability, scalability, and consumer awareness to make sustainable cutting boards mainstream.

✅ Manufacturers must embrace responsible sourcing, sustainable packaging, and educational marketing to stay competitive in the green market.

By investing in sustainability, the cutting board industry can help reduce waste, lower carbon emissions, and create a healthier planet—one board at a time. 🌍♻

www.woodencraftsliving.com